NEWS

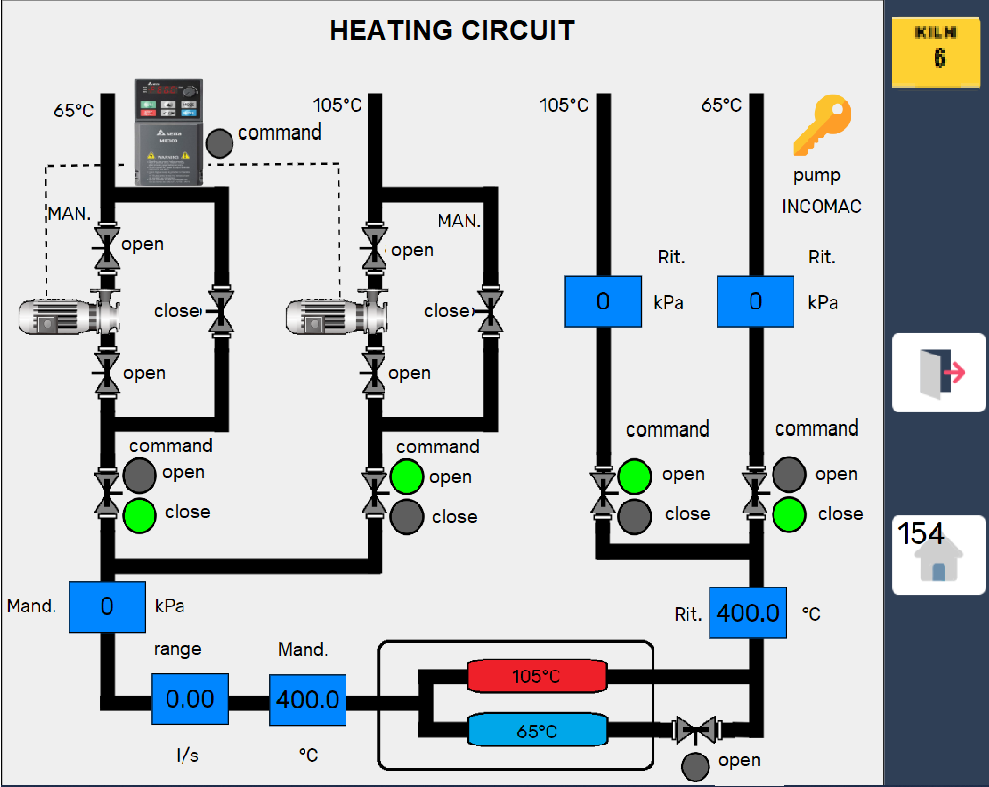

ENERGY SAVING IN THE SPOTLIGHT: CONTROL OF A DUAL HEATING SOURCE IN A NEW 7 OVEN SYSTEM IN BELGIUM

Successfully completed our latest automation project in Belgium, concluded at the end of 2023. Five dryers were involved in the upgrade, replacing the control of the old dryers with our advanced system, and the implementation of control on two new dryers.

Furthermore, software has been developed that automatically manages the selection of the heating circuit with less hot water produced by the cogeneration system. In this mode, the "residual" energy that would otherwise be wasted becomes a precious resource, contributing to the overall sustainability of the process.

Our goal is to make innovations that not only improve wood drying performance, but also have a positive impact on the environment.

Our philosophy is reflected in offering tailor-made solutions, demonstrating our commitment to providing highly efficient and customizable solutions to meet the specific needs of our customers.

20 YEARS OF RELIABILITY: CONTROL UPDATE FOR TWO OVENS IN AUSTRALIA

Following 20 years of operation, we have updated our audit history on two ovens on the other side of the world, in Australia.

In line with our commitment to value our clients' investments, we have taken a targeted approach to upgrading, focusing only on the essential elements, thus preserving the client's initial investment.

This step forward is a celebration of the robustness that our system has offered for so long, and is a testament to our focus on maximizing value for our customers. The update carried out in October 2023 introduces new features, maintaining the foundation of reliability that has defined our technology over the years.

A commitment to providing solutions that stand the test of time is at the heart of our goals. We are grateful for the trust of our customers in Australia and around the world and remain committed to offering technologies that continue to exceed expectations.

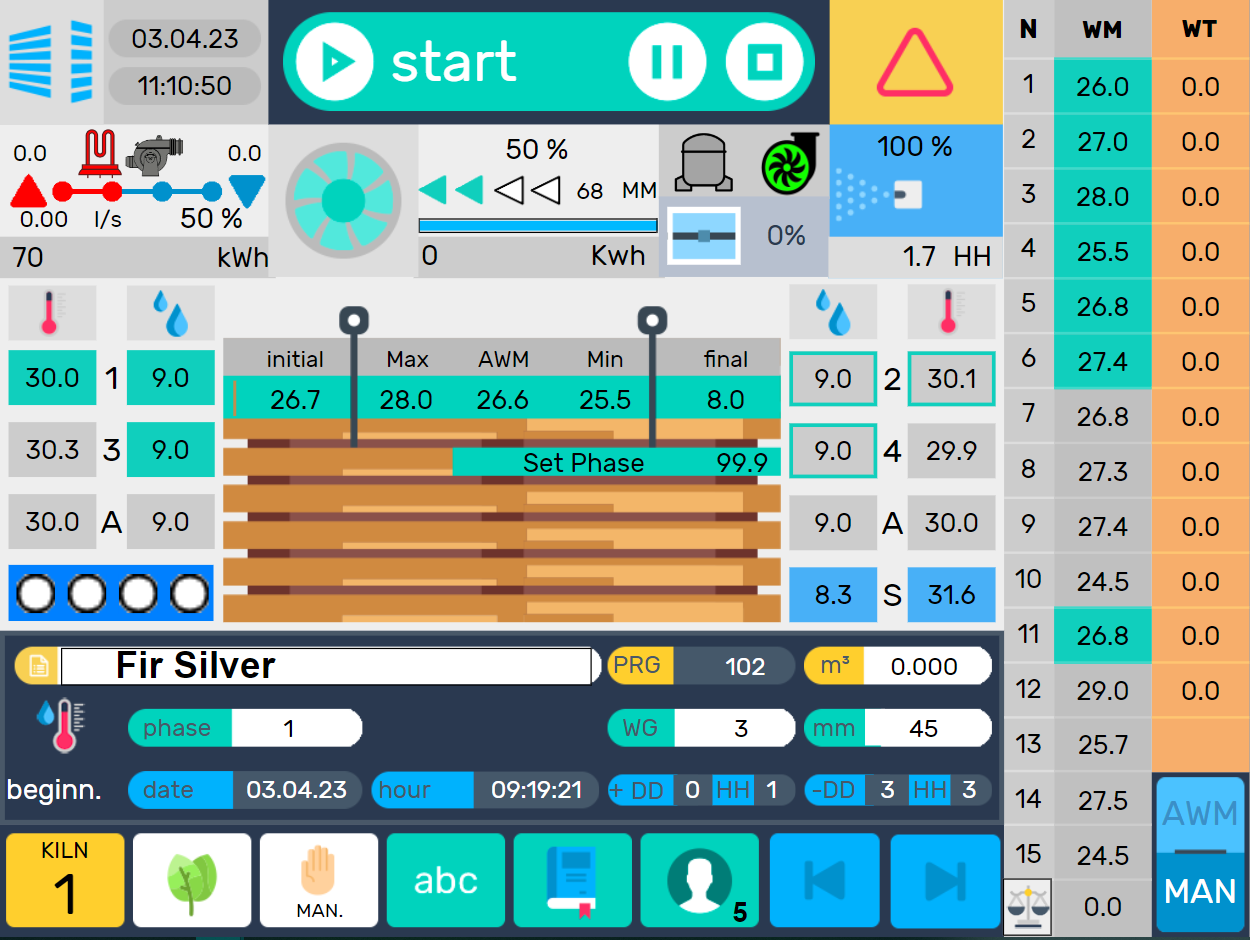

CONTROL DEVELOPED FOR HYBRID CONDENSATION AND CONVENTIONAL DRYERS

In April 2023 we developed a new type of control for drying systems with a heat pump system alongside the conventional heating and drying system. Through this mode the dryer achieves high energy efficiency by reducing consumption in the low temperature and high air humidity phases.

OUR CONTROL INSTALLED ON AN OVEN IN HUNGARY WITH INSTALLATION OF INVERTERS FOR ENERGY PURPOSES

In March 2023, a wood treatment oven installed in 2003 was updated with our application and the PCD1.M0160 PLC. Furthermore, inverters were added, thus making the system more energy efficient.

OUR CONTROL INSTALLED ON A NEW CHEMICAL-PHYSICAL PLANT

In November 2022 we developed and installed our control on a multi-stage chemical-physical treatment and activated carbon filtration plant.

This system allows the removal of polluting substances present in the water.

OUR CONTROL INSTALLED ON A BIOMASS BOILER

In October 2022 we installed our control in a biomass boiler in the Rosà area (VI). This boiler joins other boilers, in which our control is installed, present in Italy, Hungary and Romania.

OUR CONTROL INSTALLED ON TWO OVENS IN POLAND

In Poland in July 2022, two wood treatment ovens installed in 2004 have been updated with our application and the PCD1.M0160 PLC.

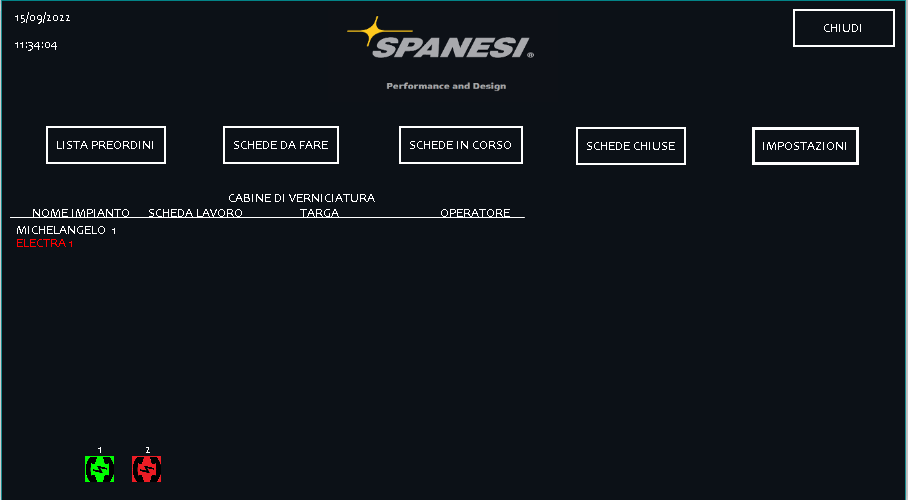

A NEW MES DEVELOPED IN THE SECTOR OF EQUIPMENT FOR BODY SHOPS AND INDUSTRIAL PAINTING PLANTS

MADE WITH OUR CONTROL THE OVEN OF AN AUSTRIAN FORESTRY INSTITUTE

OUR CONTROL INSTALLED ON A NEW MULTIFUNCTIONAL TREATMENT PLATFORM

In May 2021 in Porto Marghera (VE) we installed our control on a chemical-physical treatment and multi-stage activated carbon filtration plant for the reduction of PFAS from leachates.

WE START TO OPERATE IN THE ENERGY AND HOME AUTOMATION SECTOR

Since 2021, thanks to our experience in building automation, we have started to operate in new sectors concerning residential buildings, in particular: