INDUSTRIAL AUTOMATION

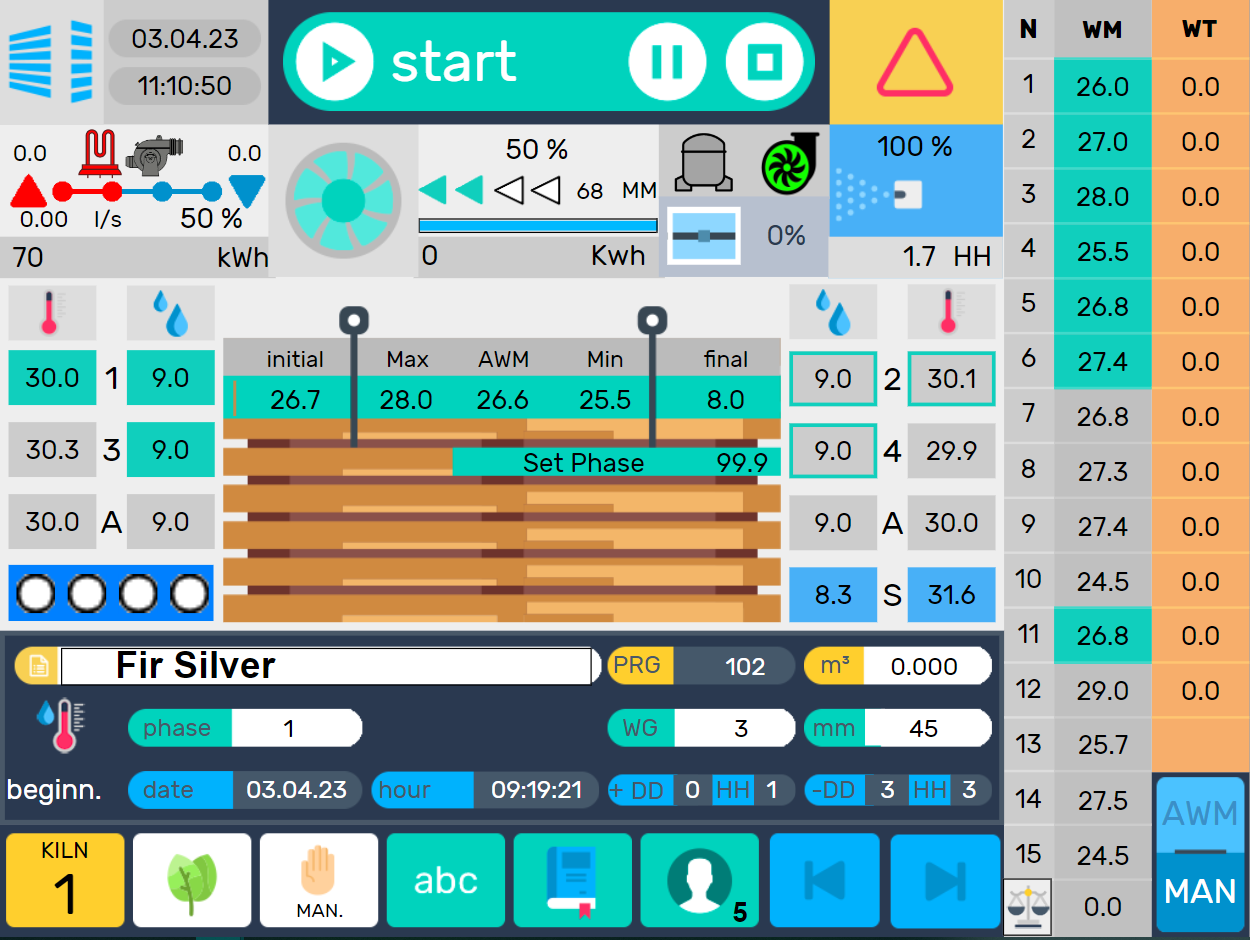

WOOD DRYING

Process automation for drying kilns, heat treatment in accordance with FAO-ISP15 and evaporation.

The experience in this sector is twenty years first as manager at Secea Essiccatoi srl and then directly with an installed 700 kilns.

Automation is carried out using industrial control equipment whose application software is developed by our company.

BIOMASS BOILERS

Automation for boilers that use wood chips or sawdust by regulating air and supply of material to optimize the combustion process.

The experience in this sector is twenty years first as manager at Secea Essiccatoi srl and then directly with an installed of about twenty boilers.

PAINT BOOTHS

Bodywork oven

Maximum efficiency and at the same time low energy consumption which translates into cost savings.

Possibility to check the times and consumption of each work session thanks to a

highly evolved Touch screen panel that also allows:

Have access to the web

Forward anomaly alerts via e-mail, thus initiating the remote assistance process

Download the instruction manual

View a video on the operation of the cabin

Maximum efficiency and at the same time low energy consumption which translates into cost savings.

Possibility to check the times and consumption of each work session thanks to a

highly evolved Touch screen panel that also allows:

Have access to the web

Forward anomaly alerts via e-mail, thus initiating the remote assistance process

Download the instruction manual

View a video on the operation of the cabin

BUILDING SECTOR

Stretching and pre stretching management.

Control unit pulls ropes for prestressed

Control unit pulls ropes for prestressed

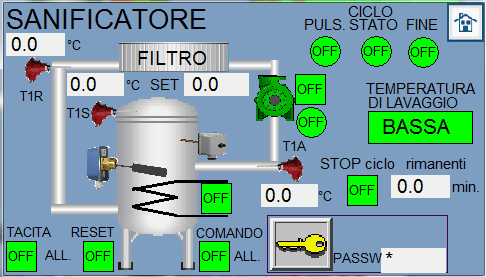

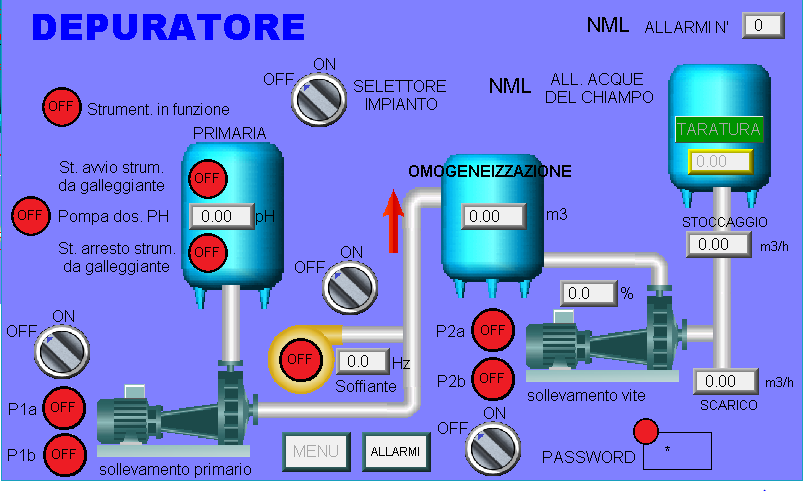

WATER PURIFICATION PLANTS

Through the panel the operator is able to know the status of the purification plant and to manage its operation.

The program consists of pages dedicated to the various functions such as the management of tanks, pumps, blowers, storage, etc.

The program consists of pages dedicated to the various functions such as the management of tanks, pumps, blowers, storage, etc.

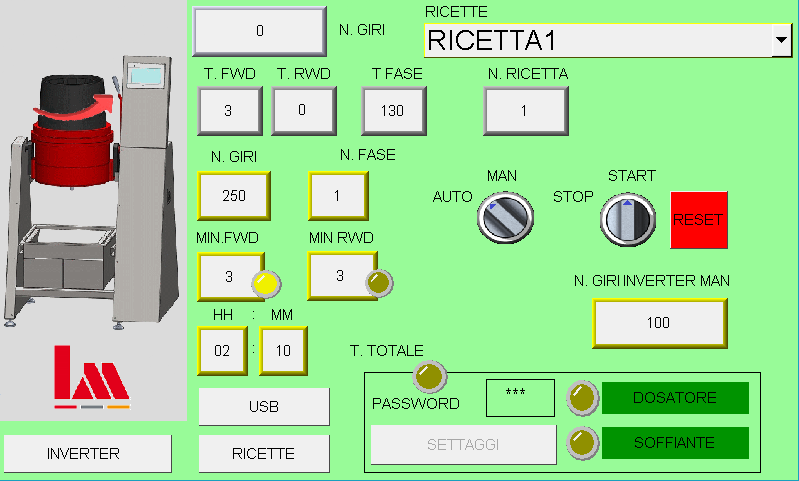

PRECIOUS METAL TREATMENT

Finishing treatment plants for precious metals and small metal parts in general for the gold and industrial sector.

Management of cleaners type PM1500 and PM3000, of the Modular Turbo 30 lt, etc ...

Through the panel the operator is able to know the operating status of the machine, give commands for switching on and off, set the adjustment parameters and possibly insert and modify recipes.

Management of cleaners type PM1500 and PM3000, of the Modular Turbo 30 lt, etc ...

Through the panel the operator is able to know the operating status of the machine, give commands for switching on and off, set the adjustment parameters and possibly insert and modify recipes.

INDUSTRIAL LAUNDRY

Restoration of fabrics through their hygiene and cleanliness.

Through a conveyor belt they are inserted in the uninterrupted washing machine: an industrial washing machine composed of eight compartments in which the garments are washed and sanitized with industrial detergents (softeners, neutralizing agents) with high cleanliness and low environmental impact.

After a drying period that must maintain the right degree of humidity, the garments pass to the ironing and final drying phase. At the exit the automatic folder folds them, stacks them in packages and packs them for storage in the warehouse and subsequent delivery to the customer.

Through a conveyor belt they are inserted in the uninterrupted washing machine: an industrial washing machine composed of eight compartments in which the garments are washed and sanitized with industrial detergents (softeners, neutralizing agents) with high cleanliness and low environmental impact.

After a drying period that must maintain the right degree of humidity, the garments pass to the ironing and final drying phase. At the exit the automatic folder folds them, stacks them in packages and packs them for storage in the warehouse and subsequent delivery to the customer.

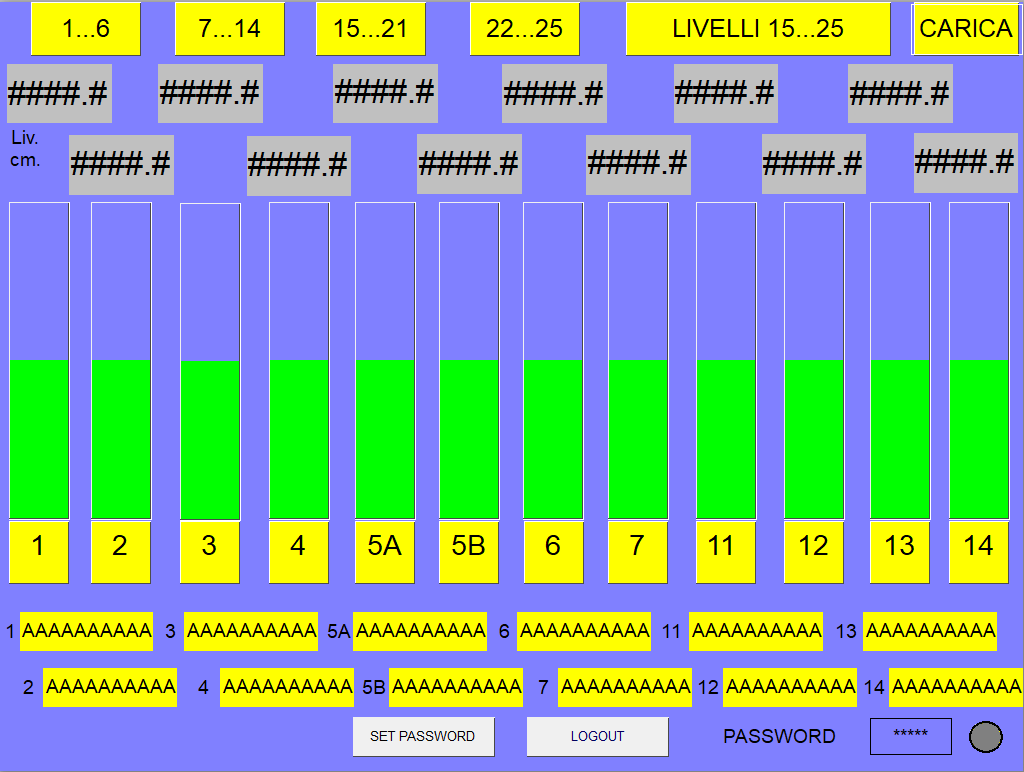

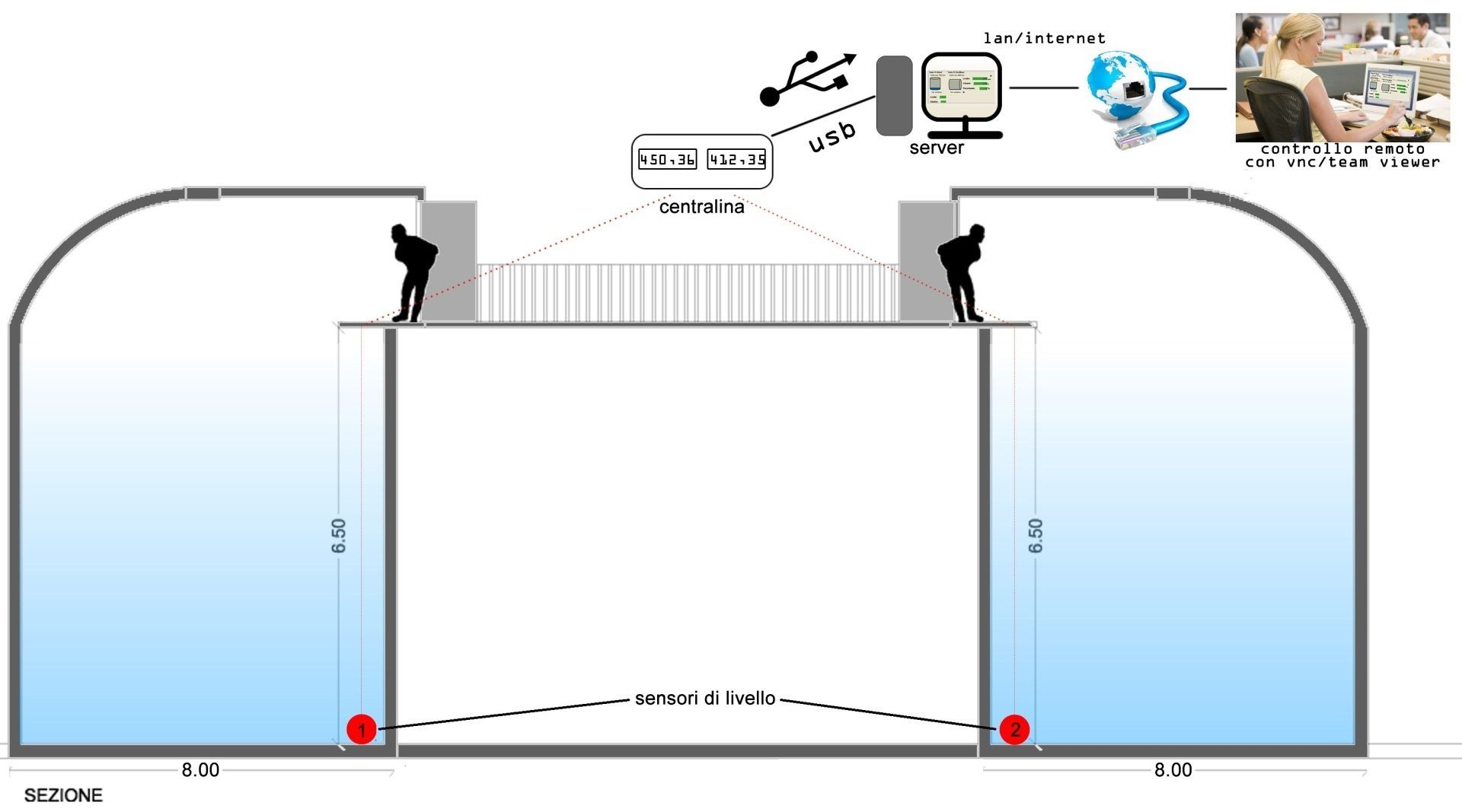

TANK LEVEL MEASUREMENT

Tank level monitoring systems. Filling the tanks through pumps managed according to the present level and to hourly and daily tables.

Measurement using pressure and radar sensors.

Measurement using pressure and radar sensors.

TREATMENT AND DISTRIBUTION

WATER

Nigeria: Mobile plant for the treatment of

water purification and subsequent water distribution

via Mobile App.

water purification and subsequent water distribution

via Mobile App.

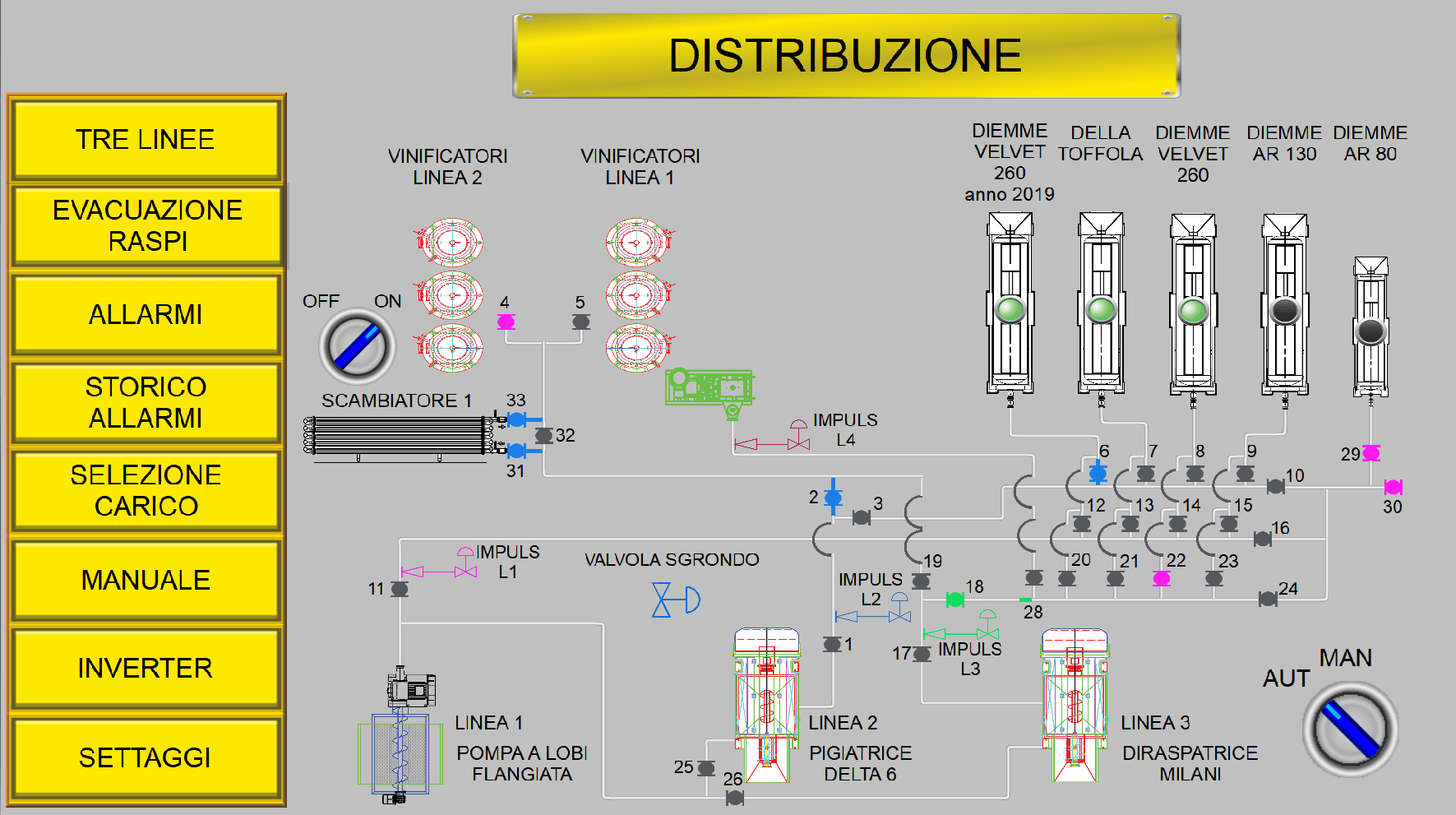

VINIFICATION PLANTS

Plants for the automation of the process of transforming grapes into wine.

Vinification with maceration, racking and pressing.

Management of multiple processing lines, possibility of automatic and manual cycle control.

Vinification with maceration, racking and pressing.

Management of multiple processing lines, possibility of automatic and manual cycle control.

FOOD INDUSTRY

Control of food production lines. Automation of conveyor belts, pickup trolleys, collection trays and lasagna counters.

WATER TREATMENT

Water treatment plant management.